LPCB Approved Sprinkler Tanks Supplier

Due to the dangerous and destructive nature of fire, fire protection systems and their components must meet the stringent regulations outlined in LPS1276 Issue 2.0 standard. Sprinkler systems are only effective if designed, installed, and maintained correctly. The LPS 1048-1 scheme: Requirements for the approval of Sprinkler Contractors in the UK and Ireland, ensures that installers are capable of designing, installing, and servicing sprinkler systems to acceptable installation standards. Sprinkler Systems were originally developed for the protection of property or equipment, however, in recent years they have been used for the purpose of life safety as an aid to the means of escape of personnel. Sprinkler System Pressure Tanks are multifunctional. They are designed for fire detection, alarm, and suppression of fire.

LPCB Sprinkler Tanks Capacity

Tricel Weston sprinkler tanks range in capacity up to 1,300m3.

Sprinkler Tanks are manufactured from GRP, as its robust properties are excellent for longevity and durability. They are also constructed to ensure minimal maintenance is required, limiting the necessity to drain down the tank during maintenance work. benefits to GRP water tanks also include: GRP Water tanks Corrosion-resistant, GRP Tested High Strength Factor vs Alternatives, Maintenance of GRP, Lightweight Capabilities GRP vs Alternatives, GRP Lower Production, Installation, Maintenance, and Transport Cost.

LPCB Approved Sprinkler Tank Capacities to Suit all Applications

Water capacity is dependent on a number of factors applicable to individual applications. Capacity levels are determined by the following:

Hazard classifications – usually the larger the hazard, the greater volume of water is required

- Ordinary Hazard Group 1 – minimum full capacity 27,500 – 40,000 litres.

Typically used for Hospitals, hotels, libraries (excluding book stores) restaurants, schools & offices. Data processing offices.

- Ordinary Hazard Group 2 – minimum full capacity 105,000 – 140,000 litres.

Typically used for laboratories, Laundries, car parks, leather goods factories & museums.

- Ordinary Hazard Group 3 – minimum full capacity 135,000 – 185,000 litres.

Typically used for Broadcasting studios, railways stations, plant rooms, farm buildings. Department stores & shopping centres. Paper/cardboard/bookbinding factories.

- Duration of water supply

- Mains refill capabilities – refill duration limits are outlined in BS EN12845

- Full holding or reduced capacity – reduced capacity may be acceptable where the main refill capabilities are sufficient to make up the water requirement balance within the “time” regulations for specific hazard classifications

- Wet or dry pipe system

- Range between the highest and lowest sprinkler. Sprinkler design standard

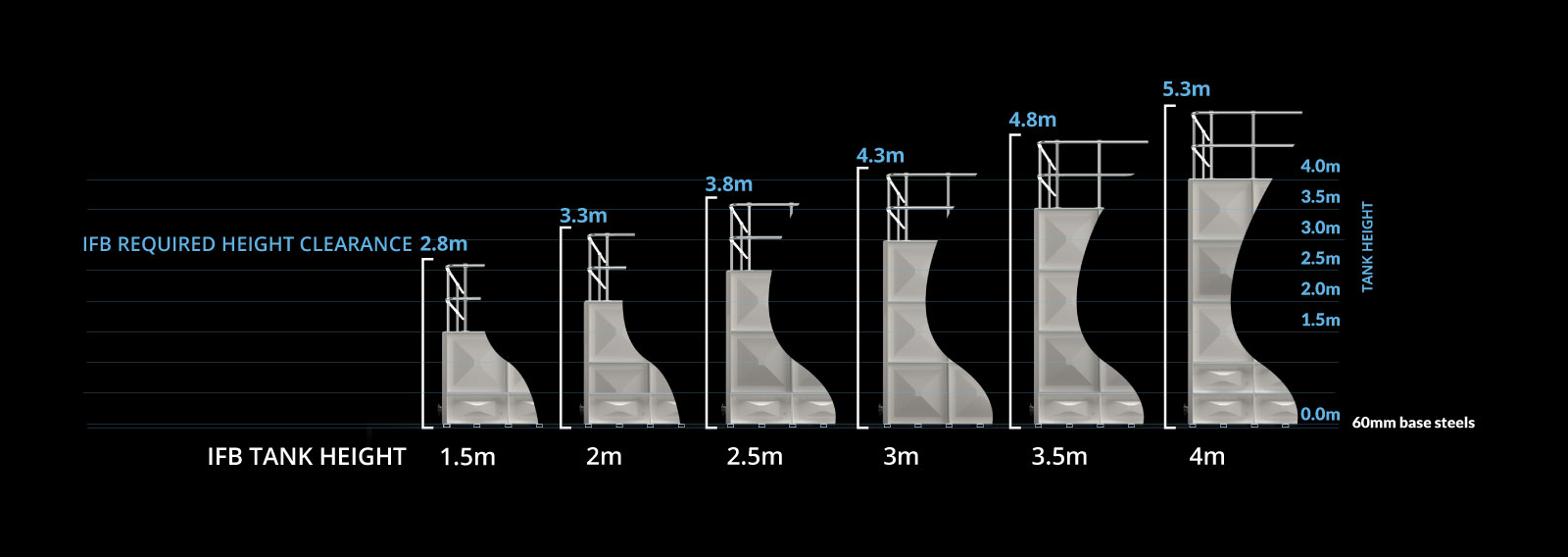

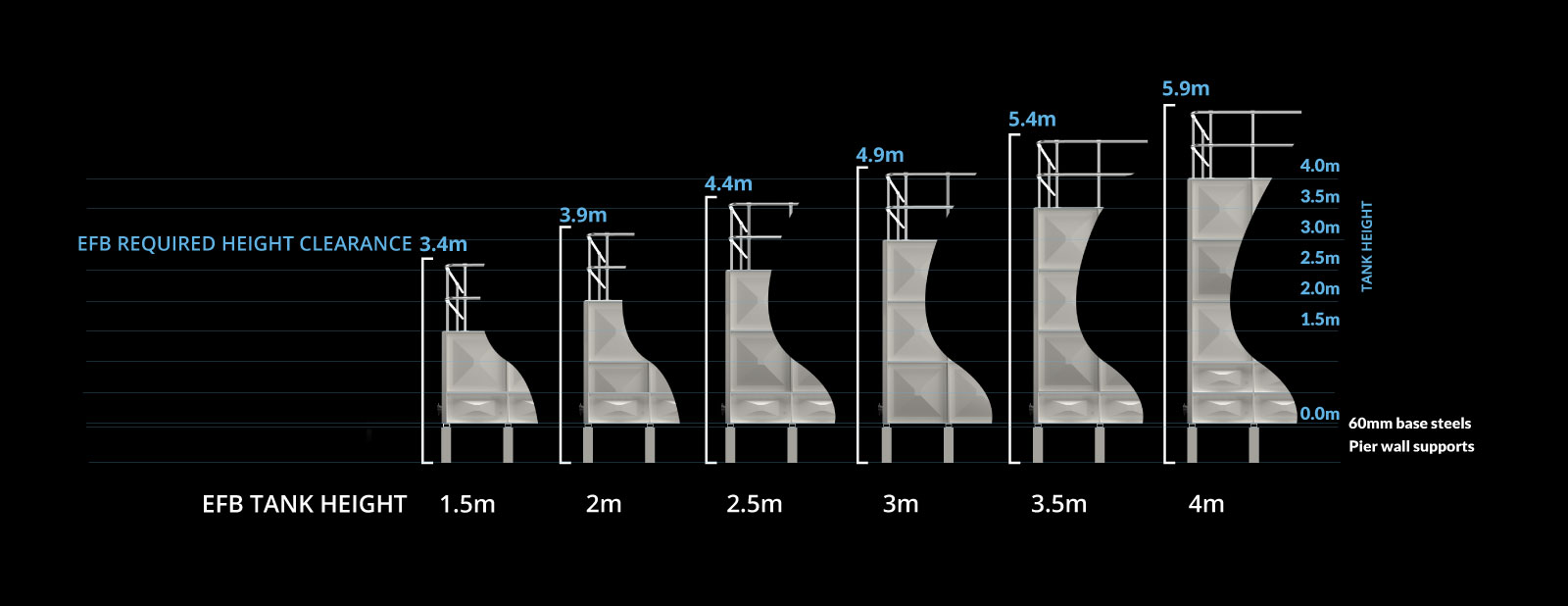

REQUIRED HEIGHT CLEARANCE WITH MANDATORY GUARDRAIL AND BASE STEELS

From the finished floor level (FFL) to the ceiling height.

| TANK TYPE | TANK HEIGHT | CLEARANCE REQUIREMENT | HEIGHT CLEARANCE |

|---|

| IFB | 1.5m | 500mm | 2.8m |

| IFB | 2.0m | 500mm | 3.3m |

| IFB | 2.5m | 800mm | 3.8m |

| IFB | 3.0m | 800mm | 4.3m |

| IFB | 3.5m | 1000mm | 4.8m |

| IFB | 4.0m | 1000mm | 5.3m |

| TANK TYPE | TANK HEIGHT | CLEARANCE REQUIREMENT | HEIGHT CLEARANCE |

|---|

| EFB | 1.5m | 500mm | 3.4m |

| EFB | 2.0m | 800mm | 3.9m |

| EFB | 2.5m | 800mm | 4.4m |

| EFB | 3.0m | 100mm | 4.9m |

| EFB | 3.5m | 1000mm | 5.4m |

| EFB | 4.0m | 1000mm | 5.9m |

Operational Requirements of a BS EN 12845 & LPS1276 Issue 2.0 (LPCB) Approved Sprinkler Tank

The water storage tank shall provide water for automatic fire sprinkler systems.

The water tank shall be designed such that the need for emptying the tank for first time maintenance shall be a period of not less than 10 years. This period excludes the need for maintenance caused by accidental damage or exceptional circumstances. Tanks should be subject to regular inspection and maintenance of ancillaries in-line with the Approved Companies’ specifications.

Ancillary Equipment as standard

*download our glossary of terms*

External Ladders & Safety Guardrail

To enable personnel access for the maintenance and/or test of float or ball valves and other ancillary equipment, whilst keeping both feet on the platform, a permanently attached access ladder shall be provided for all tanks, which incorporates a platform and guard-rail. The ladder and access platforms shall conform to BS 4211. (images required)

Note: Where alternative access provision is required this will require separate approval by BRE Global.

Internal Access Ladders

To enable personnel to enter the tank, internal access ladders, where fitted, shall be designed to be corrosion resistant.

Ball or Float Valve

A ball or float valve for maintaining the required level of water in the tank shall be installed.

The valve shall be LPCB listed to LPS 2083 The Requirements and Test Procedures for the LPCB Approval of Automatic Water Level Control Valves for use in Above Ground Suction Tanks for Sprinkler Systems.

An access opening in the tank cover shall be provided. This shall be of such size and location to enable the testing, maintenance and replacement of the ball valve equipment. The cover of this opening shall be permanently attached by hinges or other means. It shall be securely latched when closed and be capable of being opened by hand.

Tank Level Indicator

The tank shall include a device to show the total amount of water present and which monitors the quantity of water down to below the suction pipe outlet to the pumps.

This device shall be capable of being maintained without draining the tank. The primary gauge shall be fitted to the external face of the tank at a height not greater than 1.75m from the tank base. Any additional remote readouts shall be suitable for use in the location in which are they are placed.

Note: “cat and mouse” type indicators are not accepted.

Inlet Valves & Associated Flow Rates

Refill rates for full capacity tanks in BS EN 12845 states that ‘The water source shall be capable of refilling the tank in no more than 36 hours’.

To view the available inlet valve flow rate chart for use in our LPS 1276 Issue 2.0 accredited tanks, please view our chart here.

Immersion Heaters

Any immersion heater provided must be of a type that shall not burn out when exposed to the air, e.g., when the water level in the tank is lowered below the immersion heater. The heater shall be of the dual element type. Each element shall be capable of operating independently and preventing water in the vicinity of the ball or float valves from freezing, to maintain the operational function of the tank. Each element shall be capable of being maintained or removed without draining the tank;

The provision of an immersion heater can be omitted only where the ambient water tank temperature around the ball or float valve can be maintained or shown not to drop below 4°C.

Drain down facility

The tank shall be fitted with a drainage facility that will enable the tank to be emptied for maintenance and inspection purposes.

Vortex Inhibitor

The tank shall be fitted with an outlet pipe to feed the sprinkler suction pumps. An LPCB approved (LPS 2070) Vortex Inhibitor shall be fitted to the inlet of the outlet pipe.

Overflow and Warning Pipe

An overflow arrangement in compliance with the relevant water authority requirements shall be installed.

Manway

An access hatch at the base of the tank with a minimum opening of 600mm x 600mm or 600mm diameter shall be provided.

Stop Valves

Where required, LPCB approved (LPS 1185) stop valves shall be used.

10% Level Switch

A level switch linked to the BMS to advise when the effective capacity volume has reduced by 10%.

Balance Pipes

Where balance pipes are installed, stop valves shall be fitted to enable isolation of each tank for maintenance. These valves shall be monitored.

GET A FREE QUOTE

TRUSTED BY OUR CUSTOMERS THROUGHOUT THE UK & THE WORLD

No logos found

“The installation process was smooth and very efficient.

We will continue to use Dewey Waters as the service we receive is always excellent.”

Product supplied: Sectional Tank HLU TIF 2.25m x 1.00m x 2.00m

★★★★★

Fully Certified LPCB Sprinkler Tank Manufacturer

Tricel Weston is an accredited & certified GRP water tank manufacturer. We pride ourselves on operating to the highest professional standards. We are committed to supplying our customers with genuine market-leading, high-quality products, and always strive to provide the most appropriate solutions to fulfil clients’ needs. Our product range and manufacturing processes are continually updated and optimised to ensure that we offer the most up-to-date products and services – improvements which are driven by a combination of legislative change, fluctuating market forces and consumer demand. To ensure consistent levels of product quality, we regularly monitor our procurement and usage of raw materials, whilst also striving to adopt the most efficient production methods – using natural resources in all of our manufacturing processes where possible.

DEWEY WATERS FEATURES

Specialising in the manufacture of both one piece and sectional cold water storage tanks, our experience ensures that we are able to accommodate virtually all client requirements.

On time Delivery

Placing and receiving your order is a straightforward, hassle-free process.

Technical Advice

We provide high levels of technical knowledge, product choice and customer service.

Fully Certified

Dewey Waters is an accredited & certified GRP water tank manufacturer.

Experts Installation

60 years’ industry experience in both Water Storage and GRP industries.

On Time Delivery

Placing and receiving your order is a straightforward, hassle-free process.

Technical Advice

We provide high levels of technical knowledge, product choice and customer service.

Fully Certified

Dewey Waters is an accredited & certified GRP water tank manufacturer.

Experts Installation

60 years’ industry experience in both Water Storage and GRP industries.